- Top

- Investor Relations

- Our Initiatives

Our Initiatives

What does Nihon Dengi do?

We create high-quality spaces tailored to the purposes of each building while taking the global environment into consideration.

By using instrumentation technology to control air conditioning equipment in non-residential structures such as buildings and factories, we are helping to save energy while supporting building comfort and production efficiency.

Nihon Dengi’s technologies at work around us

Office buildings

Along with an increase in the construction of advanced buildings in recent years, the value of historical buildings has been recognized and their preservation and maintenance (refurbishment) strengthened, leading to a growing demand for air conditioning equipment and energy-saving solutions tailored to the purposes and specifications of each building. In response to these changes in the environment, we provide instrumentation systems that offer the comfort, safety, and eco-friendliness that future generations deserve.

Factories

We are involved in setting up automatic control of production lines for food and pharmaceutical products, thereby supporting not only higher productivity but also safety and quality assurance through the use of various systems. We also propose new solutions such as labor-saving and energy-saving measures that utilize industrial robots.

Hospitals

Hospitals require not only temperature control but also appropriate humidity control for maintaining clean air and preventing nosocomial infections. Operating rooms, in particular, must comply with air conditioning standards and require air conditioning control that utilizes differential pressures for ventilation to improve air quality. Our equipment works around the clock and contributes to the maintenance of healthcare environments for saving lives.

Post offices and newspaper companies

We are involved in setting up automatic control of conveying lines for small packages and newspaper bundles. Advanced automatic control is necessary at distribution sites, where the appropriate conveyance speed and accurate sorting are vital. We have built systems featuring advanced designs by leveraging our engineering experience to cater to a wide range of needs, including the integration of machines from different conveyance equipment in an efficient manner to improve work efficiency.

In addition, Nihon Dengi’s technologies have been utilized in research facilities, cleanrooms, cultural facilities such as museums, and in many other buildings around us.

Did you know? The founding of Nihon Dengi and the origin of its name

Yamatake Keiki Co., Ltd. (now Azbil Corporation) entered into a capital alliance agreement with Honeywell, a leading control equipment manufacturer in the United States, in 1952.

As the import and domestic sale of air conditioning control equipment began in Japan, there was a need for instrumentation work companies to install instrumentation equipment.

Spurred by their belief that the air conditioning instrumentation business would continue to grow, the Company’s founding management team (Shichiryo Shimada and seven others) established Nihon Dengi Co., Ltd., as a company that specializes in air conditioning instrumentation work in 1959.

Origin of company name: The Company was named “Nihon Dengi Co., Ltd.” to reflect its ambition to become the top Japanese company in electric technologies.

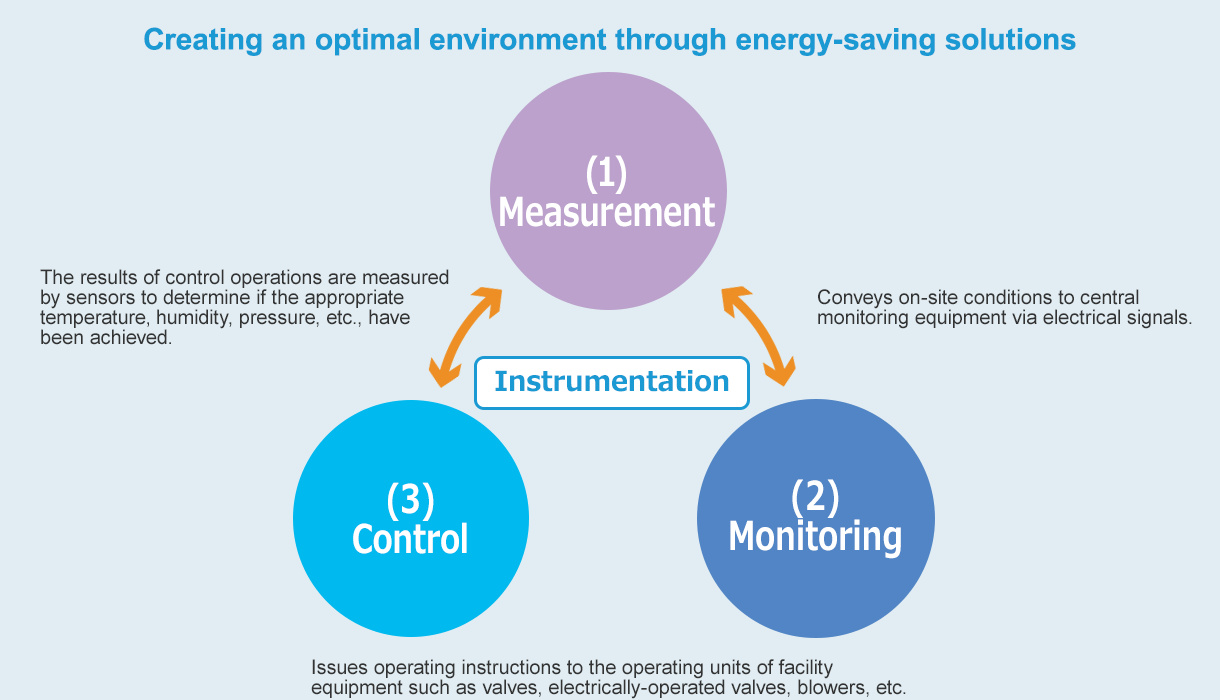

What is instrumentation?

Instrumentation refers to technologies that automatically control building equipment to achieve greater comfort, efficiency, labor efficiency, and energy efficiency.

In the case of instrumentation for air conditioning in buildings...

The cycle of “measurement ⇒ monitoring ⇒ control” serves to measure the temperature, humidity, pressure, etc., monitor the measured information by means of computers, and control the facility’s equipment to maintain a certain set of environmental conditions, thereby achieving greater comfort and energy efficiency through control of the entire facility.

(1) Sensors

Sensors are installed to measure temperature, humidity, pressure, etc., and other variables to be controlled.

(2) Central monitoring equipment

Central monitoring equipment aggregates the information received from sensors in computers. The aggregated information is processed and used to issue commands designed to achieve the optimal environment.

(3) Facility equipment

Valves, electrically-operated valves, and blowers are operated to control the flow of hot/cold water and the amount of electricity accordingly to create an optimal environment.

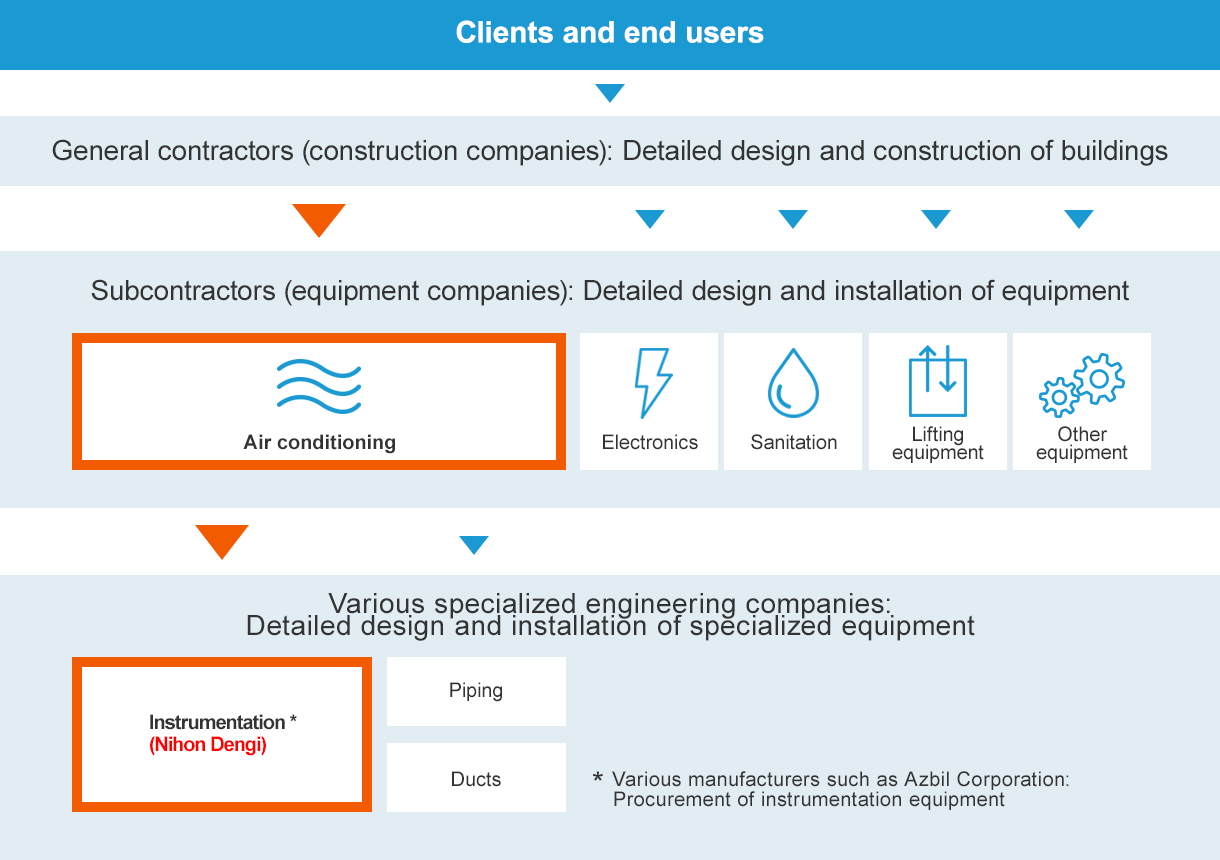

What is air conditioning instrumentation in the construction industry?

Did you know? Affiliated parties and Nihon Dengi’s position

For new building automation projects, we receive orders for air conditioning instrumentation work from subcontractors (equipment companies) tasked with the detailed design and installation of equipment. After the building is completed, we are not only tasked with the ongoing maintenance of air conditioning equipment but also receive orders directly from end users (building owners, etc.) for renovation work and support for asset management and asset value enhancement of the building.

For factory automation and process automation projects, we receive orders directly from customers who are primarily end users (manufacturers, etc.). Even after receiving an order, we always follow up with the customer to provide solutions that are tailored to their needs.

The environment surrounding Nihon Dengi

The air conditioning instrumentation industry, our core business, has a market size of ¥166.0 billion! (based on our research)

Business environment

Air conditioning instrumentation-related business

New installation work

- Continued redevelopment projects in the Tokyo metropolitan area and steady growth in public-sector property projects

Work for existing facilities

- Downsizing of offices and other renovation projects expected in the post-COVID era

- Growing demand for energy-saving measures to achieve a carbon-neutral society

Industrial systems-related business

- Growing demand for automation due to a decrease in the number of workers in the manufacturing industry, etc.

- Increase in projects such as manufacturing equipment renovations and system upgrades to create smart factories

- Steady growth in construction projects for production management systems for food factories, etc.

Long-term outlook

Japan aims to achieve carbon neutrality by 2050 and a 46% reduction in greenhouse gas emissions from FY2013 levels by FY2030. These energy policies underpin a long-term vision to create a carbon-neutral society, with the market for environmental businesses expected to expand steadily. Especially in the case of the construction industry, efforts are being made to achieve ZEB, the ultimate energy-saving solution where buildings are concerned, which leads us to believe that the demand for energy-saving and labor-saving solutions that can be implemented with our technologies is expected to grow further.

Furthermore, in the case of Japan’s manufacturing industry, factories are expected to expedite their efforts to transition to smart factories that take advantage of digital transformation such as AI, IoT, and ICT technologies. This will potentially spark greater demand for projects related to the construction of production management systems and the upgrading of factory equipment, including process automation (PA) and factory automation (FA).

*ZEB: Net-zero energy buildings

Did you know? Contributing to the achievement of carbon neutrality by 2050

A carbon-neutral society is one in which carbon dioxide (CO2) emissions, a main cause of global warming, are reduced to net zero. It is imperative to implement large-scale energy-saving solutions to create a carbon-neutral society. The movement to transition to a carbon-neutral society presents vital business opportunities for Nihon Dengi, which has sought to create optimal environments for buildings, factories, and other structures by using as little energy as possible. We will contribute to the achievement of a carbon-neutral society while pursuing new possibilities for instrumentation.

Nihon Dengi’s strengths

A pioneer in instrumentation with superior engineering capabilities.

Given our position as the only major company in the industry that specializes in engineering, our wealth of experience has earned us the trust of customers.

Breaking new ground with the comprehensive capabilities of instrumentation Comprehensive engineering capabilities

Technical capabilities developed over a long history

Instrumentation is said to be experience-based engineering, and the number of sites we have worked on sets our technical capabilities apart from that of other companies.

We have the longest track record in the industry and a wide range of work experience, which contribute to our superior engineering capabilities.

Competitive advantage in the market of existing facilities

Our portfolio consists of a wide range of existing facilities owing to our long track record. The market of existing facilities is considered one with massive future potential due to the growing demand for energy-saving renovation work, allowing us to expand our business from an advantageous position.

Adapting our expertise to address the needs of various fields

By deploying our technical capabilities developed in the air conditioning instrumentation field in other industrial domains (such as PA and FA), we are confident in the future growth of Nihon Dengi as a comprehensive engineering company.

Medium-term management plan (overview)

65th medium-term business targets (fiscal year ending March 2024)

- ROE target

10% or higher - Operating profit target

¥4.5 billion - Net sales target

¥35.0 billion - Target amount of orders

¥32.5 billion

We, Nihon Dengi, will pursue the possibilities of instrumentation through our superior engineering technologies and contribute to creating a better environment for people and the earth through our business activities.